What should we pay attention to when installing linear guide rails?

As an important moving component, linear guides are an indispensable component for many machines. So many customers need to install them by themselves after purchasing linear guides. What should they pay attention to when there are no technical personnel present? Let’s talk briefly today. You can consult our technical staff for specific operations.

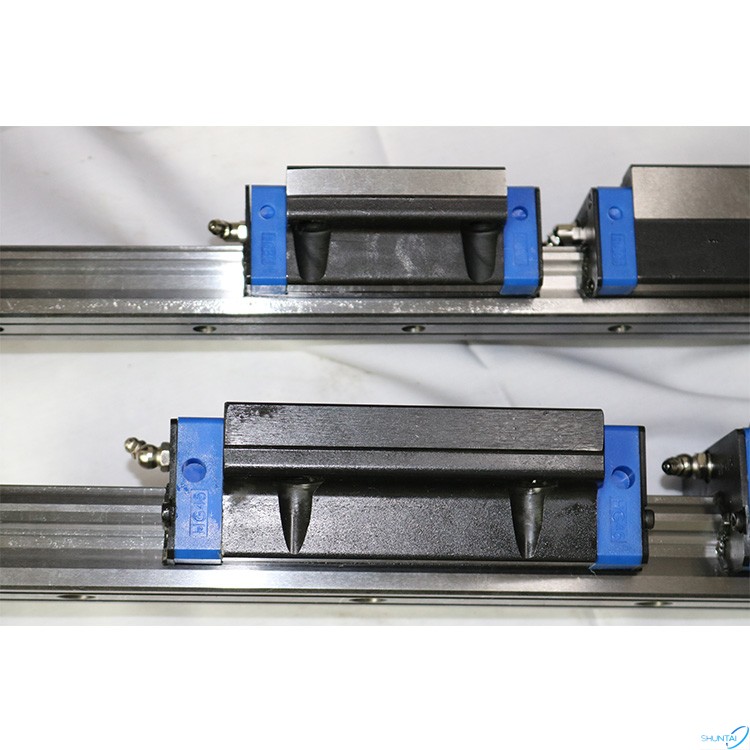

The first thing to note is not to remove the slider from the guide rail at will. Normally, we ship the slider and the guide rail together, which means that the slider is of good quality, because there are balls inside the slider. If you take it out without paying attention, it may cause the balls to slip. If the ball is lost, the slider cannot be used. Generally, our manufacturer will be equipped with a slider push-off device to assist in removing the slider and reduce the occurrence of ball falling off.

In addition, disassembling the slider during assembly may cause dust and dust in the environment to fall in. After reinstalling, the motion may be stuck and the accuracy may be reduced, which is not worth the gain.

So before the formal installation, we must first carefully clean the installation location, remove burrs, dust and other dirt on the work surface, and keep the work surface smooth and tidy. In addition, it is necessary to apply anti-rust oil to the linear guide rail to prevent rust from affecting the normal function and performance of the product in future use.

Linear guide rails are usually fixed with bolts. Each model has a recommended bolt model. Customers are also asked to use the recommended sizes.

When fixing the bolts, be sure to tighten them and keep the track and the workbench close to each other without shaking. After tightening them all, drive the hole cover into the assembly bolt to keep it on the same level as the top surface of the linear guide rail.

There are some technical requirements for the assembly and installation of linear guides. We recommend that our customers find relevant technicians or consult the manufacturer for technical support during organization and installation.