Processing Advantages of Gantry Shears

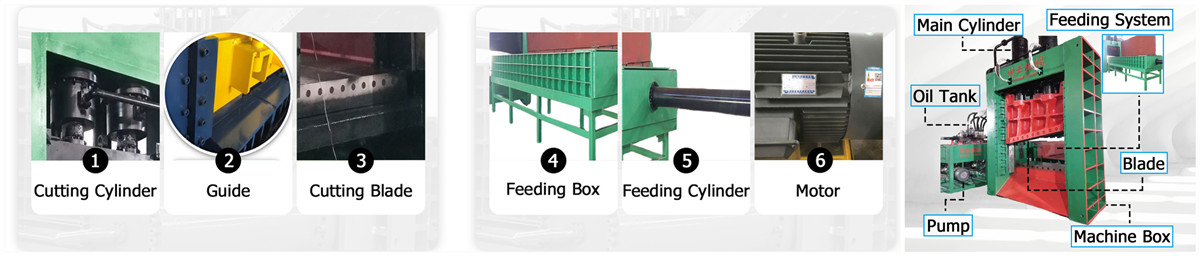

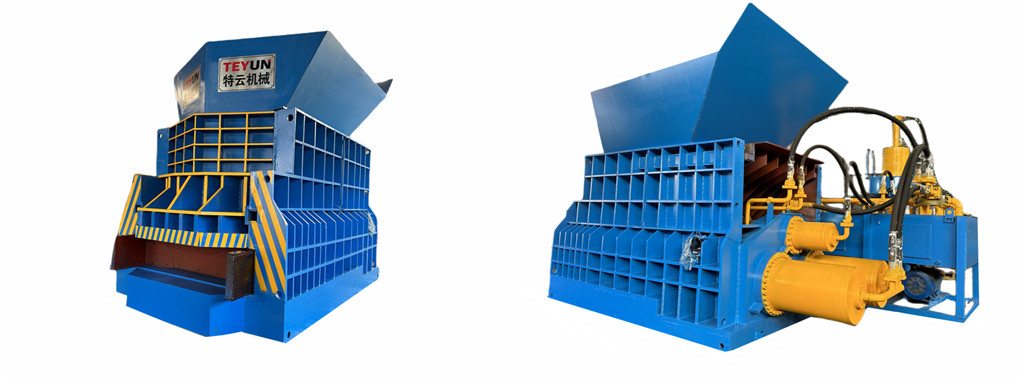

1. The gantry shear has excellent shearing performance

It adopts high hardness blades and sturdy shear structure, which can easily cope with the shearing needs of different materials. Whether it is thin plate material or thicker metal plate, the gantry shear can stably and quickly complete the shearing task, to ensure that the cutting surface is flat and smooth. Moreover, the shearing speed of the gantry shear can be adjusted according to the needs, so as to meet the processing requirements of different workpieces.

2. Gantry shears are characterized by high accuracy

Through advanced CNC technology and precision sensors, the gantry shear can realize precise control of the size and angle of the workpiece. Whether it is straight line shear or curve shear, the gantry shear can maintain a high degree of accuracy and stability. This makes it widely used in industries that require high-precision machining, such as aerospace and automotive manufacturing.

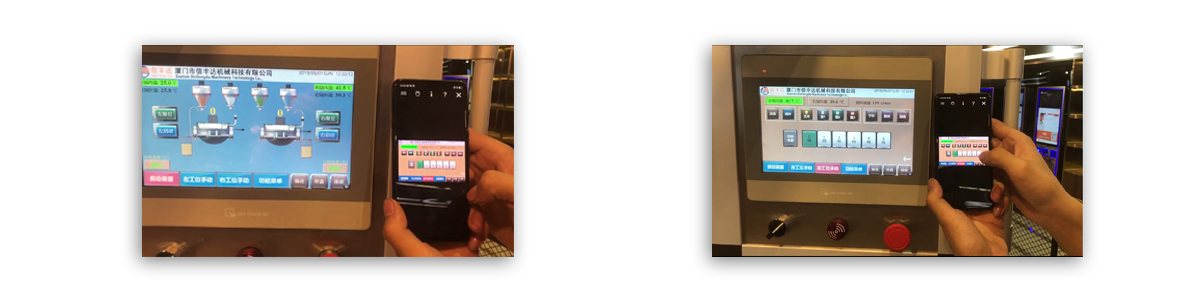

3. Gantry shear is easy to operate, easy to learn and master

Its humanized design and friendly interface enables the operator to quickly get started and quickly adjust and control the processing parameters. Moreover, gantry shears are usually equipped with safety protection devices to ensure operator safety and avoid accidents. This simplicity and ease of use provides a convenient way for companies to improve productivity and reduce labor costs.

4. Gantry shears also have a large processing range and flexibility

According to different processing needs, gantry shears can be cut in a variety of shapes and sizes. Whether it is straight line cutting, diagonal cutting or shaped cutting, gantry shears are capable of handling. At the same time, the gantry shear can also carry out multiple consecutive cutting and automatic positioning, which greatly improves the production efficiency. This flexible and diverse processing capability makes the gantry shear the ideal choice to adapt to the changing and diversified market demand.

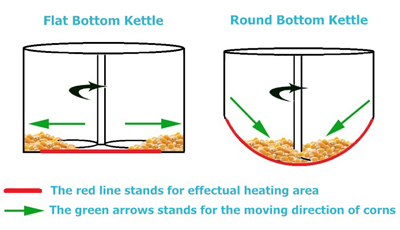

onehas big

advantages: The round bottom kettle could

avoid the centrifugal effect and ensure all the corns are in the middle of the

bottom (the effectual heating area) and well burst while the stirring rod rotating in the kettle, this directly influences

the production yield. The pelletizing ratio for jumbo (ball shape) is up to 90%-91%, which the traditional machine is only 80%-86%,

and the production yield is up to 99%. Beside, easily equipped with automatic

kettle-cleaning function by using the water droplets’ self-flow characteristic

and the stirring rod, these make it easy to clean.

onehas big

advantages: The round bottom kettle could

avoid the centrifugal effect and ensure all the corns are in the middle of the

bottom (the effectual heating area) and well burst while the stirring rod rotating in the kettle, this directly influences

the production yield. The pelletizing ratio for jumbo (ball shape) is up to 90%-91%, which the traditional machine is only 80%-86%,

and the production yield is up to 99%. Beside, easily equipped with automatic

kettle-cleaning function by using the water droplets’ self-flow characteristic

and the stirring rod, these make it easy to clean.