Precision vs Accuracy How Are They Important in Machining?

Two important elements defining the quality of machining are accuracy and precision. While accuracy gauges how closely a result is to the desired aim, precision describes how regularly a machine may repeat the same result. These two ideas are essential in manufacturing sectors where even little mistakes can cause expensive issues.

This article will discuss the value of accuracy and precision in machining and how modern technology, such as CNC machines, improves both.

What is the Difference Between Precision and Accuracy?

Though they define various aspects of measurement, accuracy, and precision are basic ideas in machining.

· Precision: Precision in machinery is the ability of a machine to perform a certain operation repeatedly. Even if the result is inaccurate, a CNC machine is said to be precise when it consistently generates the same result. Precision is about lowering variation in ongoing work. A CNC machine is accurate but not precise, for instance, if it routinely cuts metal 0.2 millimeters off target.

· Accuracy: This word describes the degree of proximity of a process's outcomes to the intended measurement. A machine is accurate if its cut exactly fits the needed specification. Accuracy by itself, though, is insufficient. Even an accurate machine might not run consistently without precision.

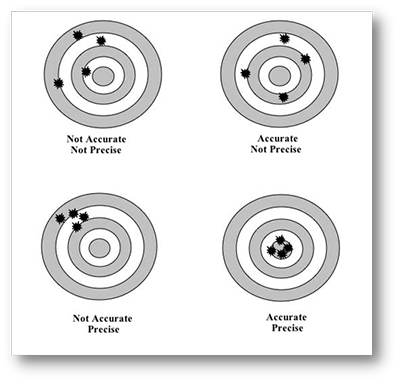

Consider a dartboard to help you understand this. Precision is when all the darts land in the same location, notwithstanding their distance from the bullseye. Though it's just one throw, accuracy is when the dart lands on the bullseye.

Excellent accuracy and precision combined with a CNC machine will help to lower material waste, increase efficiency, and satisfy the most exacting standards. That is vital in aerospace, automotive, and electronics sectors where every component must satisfy exact criteria. It Equipped with both features, a machine guarantees consistent, high-performance output.

Why Does Machining Precision Matter?

Machining requires precision for various reasons. Repeatability is among the main advantages of accuracy. In sectors like automotive or aerospace, each item must be the same even though parts are manufactured in great numbers. CNC machines guarantee that independent of production volume, every single component satisfies the same criteria thanks to their great precision.

These are the main causes of the great importance of accuracy:

· Consistency in Mass Production: A small variation can cause quality control problems throughout thousands of parts. For instance, a part may not operate as intended when assembled if it is routinely cut somewhat too small. Precision guarantees that every component is produced according to the same criteria, solving this issue.

· Reduced Material Waste: Precision machines effectively use materials, reducing waste. Any machining process flaw, no matter how little, can cause material to be modified or discarded. Along with costing more, this wastes priceless resources.

· Higher Quality Products: High precision guarantees that parts are created exactly as needed in sectors where safety and dependability rule, including medical equipment or aerospace. A product failure arising from even small differences may have disastrous results.

· Less Need for Adjustments: Precision lessens the demand for rework or corrections. Precisely produced pieces fit together, saving the need for further adjustments following machining.

In What Ways Could Accuracy Affect Machined Part Quality?

Precision guarantees repeatability; accuracy guarantees that items satisfy the intended standards. Accuracy is crucial for manufacturing important components—such as those found in medical equipment, electronics, or heavy machinery.

For instance, every flaw in a component you are machining for a high-performance engine can cause mechanical breakdown. The engine components must mesh precisely. A small difference can lead to friction, heat, and wear, degrading engine performance and lifetime. Accurate machining guarantees that every component fits together as it should.

Key Effects of Machining Accuracy:

· Meeting Tight Tolerances: Certain sectors demand items produced under very limited tolerances. Reaching these criteria depends on accurate machines. No matter how exact, inaccurate equipment can fail to reach these important tolerances and produce defective items.

· Assembly and Functionality: Accurate machining of components will result in proper fit and desired functionality. Accuracy guarantees that the product will function as intended, whether you are building a basic assembly line or a sophisticated aeronautical component.

· Improving Reliability: In sectors including medical equipment, even the smallest mistake can make all the difference between life and death. Reliable and precise operation of parts is guaranteed by accurate machining.

Accuracy vs. Precision Examples

Evaluating the performance of manufacturing activities depends much on accuracy and precision, which are independent factors. While precision indicates the machine's capacity to perform the same operation regularly, accuracy in CNC machining gauges a part's relative proximity to its intended dimensions. In order to keep specified dimensions, most CNC machines depend on computer software. Still, the outcomes may differ:

· Precise and Accurate: A CNC machine constantly generates parts with minimum errors that match the design criteria. One gets accuracy as well as precision.

· Accurate but Not Precise: Though the machine generates pieces almost within the specified measurements, the outcomes vary. While some components stray, others satisfy the criteria.

· Precise but Not Accurate: Although the machine always generates parts with the same measurements, those measurements deviate from the desired specifications. Though wrong, the parts are similar.

· Neither Precise Nor Accurate: The machine generates inconsistent pieces; none satisfy the needed standards.

Evaluating the performance of manufacturing activities depends much on accuracy and precision, which are independent factors. While precision indicates the machine's capacity to perform the same operation regularly, accuracy in CNC machining gauges a part's relative proximity to its intended dimensions. In order to keep specified dimensions, most CNC machines depend on computer software. Still, the outcomes may differ:

· Precise and Accurate: A CNC machine constantly generates parts with minimum errors that match the design criteria. One gets accuracy as well as precision.

· Accurate but Not Precise: Though the machine generates pieces almost within the specified measurements, the outcomes vary. While some components stray, others satisfy the criteria.

· Precise but Not Accurate: Although the machine always generates parts with the same measurements, those measurements deviate from the desired specifications. Though wrong, the parts are similar.

· Neither Precise Nor Accurate: The machine generates inconsistent pieces; none satisfy the needed standards.

Differentiating between accuracy and precision and independently measuring them will help to guarantee a high-quality machining operation. Examples illustrating how these two factors influence part machining are below:

1. Precision and Accuracy in Gear Manufacturing: Precision and accuracy define a CNC machine that generates gears with the right size and form for seamless operation. The machine is accurate but not exact; if the gears vary in size, they still fit appropriately.

2. Medical Device Production Accuracy: Medical equipment has high criteria. Though accuracy may be insufficient if some pieces vary, machine-produced parts with exact implant specifications could be accurate.

Knowing these differences optimizes the machining process, guaranteeing accuracy and precision for dependable, high-performance products.

Could A Machine Be Precise But Not Accurate?

A machine can be precise but not accurate at the same time indeed. In machining, this is a vital difference.

Suppose you are making cylindrical pieces on a lathe. The machine is exact since it generates the same output every time if it constantly generates pieces that are 0.5 millimeters bigger than the target diameter. The parts are not the right size; hence, they are not accurate either. That emphasizes how to separate traits—accuracy and precision—that must be optimized and call for separate optimization.

A machine can produce consistent components even if it is not accurate if it is exact; those parts will not satisfy the required criteria nevertheless. That can be a challenge in sectors like aerospace or automotive, where the pieces must precisely fit one another.

Key Differences:

· Precision: Always leads to the same outcome, even if it's wrong.

· Accuracy: generates the right outcome despite an erratic process.

Should a machine prove accurate but not exact, calibration could be necessary to fix the inaccuracy. Recalibrating the equipment can change the process to become exact and accurate.

Why Would A Machine Be Precise But Not Accurate?

Wear and tear, poor calibration, or incorrect setup can cause machines to grow imprecise or inaccurate. Even the best devices could need recalibration over time to keep accuracy and precision. Therefore, regular maintenance and calibration are essential to guarantee that devices satisfy the required criteria.

Although CNC Yangsen's machines are made to keep accuracy and precision throughout time, regular calibration helps to guarantee long-term performance.

How Do Machining Tolerances Affect Precision and Accuracy?

In machining, tolerances are deviations allowed from a given dimension. Tolerances allow a margin for slight deviations since no machine can generate precisely to specification every time.

Most machining processes find that the cost of output increases with decreasing tolerance. Tolerances are intimately connected to both accuracy and precision. Precise and accurate machines can generate parts regularly falling inside the necessary tolerance range.

Types of Tolerances:

· Tight Tolerances: These are applied even when the tiniest departure from the designated measurement could lead to issues. For an aviation engine, for instance, parts might have to be machined within a tolerance of 0.01 millimeters since even the tiniest change might compromise performance.

· Loose Tolerances: Looser tolerances can be employed in some areas where accuracy is unnecessary. For non-critical parts that won't be under stress or wear, for instance, looser tolerances allow for small variations from the intended size or form.

Machines such as the very precise CNC verticle machine centers offered by CNC Yangsen are perfect for exact tolerances. They guarantee that every part satisfies the necessary criteria by operating within quite small margins of error.

How Can You Make Machining Both Precise And Accurate?

High-quality parts require the proper mix of accuracy and precision. A precise but not accurate machine will regularly generate parts that are off. On the other hand, if a machine is accurate but not exact, it will only seldom generate parts that satisfy the criteria.

· Invest in High-Quality Machinery: Not every machine is built equal. While certain devices can offer accuracy and precision, others may be made for only one. CNC Yangsen's high-end machines provide accuracy and precision, guaranteeing constant outcomes.

· Maintain Equipment: Regular maintenance is even required of the most sophisticated machinery. Keeping machines both accurate and exact depends on proper maintenance, part replacement, and recalibration.

· Calibration: Frequent calibration guarantees machines' correctness throughout. Even the greatest machines can wander from their intended specs without calibration, producing inaccurate products.

Complex Machining Requires Precision And Accuracy, Why?

Ensuring that items satisfy the required criteria in complicated machining projects requires accuracy and precision. Complex jobs often call for a machine capable of preserving accuracy and precision throughout the process, including several processes, tight tolerances, and using several materials.

For instance, think of the manufacturing of an aircraft multi-part assembly. The whole assembly may suffer if one component is inaccurately or precisely lacking. In these situations, even little variations from the planned design can cause performance problems, safety hazards, or failure of the ultimate result.

For complex machining jobs, machines such as the 5-axis CNC machining centers from CNC Yangsen are perfect since they provide both accuracy and precision even when working with challenging materials or intricate geometries.

Complex Machining Applications Of Accuracy And Precision:

· Aerospace Components: High-precision machining guarantees that, under the worst conditions, all parts fit together exactly.

· Medical Devices: Errors in medical equipment can endanger people. Precision machining ensures the intended functionality of devices.

High-precision tools for these jobs would be CNC machining centers from CNC Yangsen. Designed to satisfy the strict criteria of various sectors, they provide accuracy and precision for the most important jobs.

How Do Precision and Accuracy Impact Efficiency and Cost?

Machining processes' cost and efficiency directly rely on accuracy and precision. Precise and accurate machines lower rework, reduce waste and boost production speed. Over time, this translates into notable cost reductions.

Accurate and exact machining of parts reduces the necessity of remakes or corrections. Because every part is created to exact standards, accurate machines help cut the time spent on quality control inspections.

Benefits of High-Precision and Accurate Machines:

· Reduced Waste: Consistent machine performance reduces waste of materials.

· Lower Rework Costs: Less time and money spent fixing mistakes equals fewer mistakes overall.

· Increased Production Speed: Faster and more dependably produced parts by precision machines raise general efficiency.

By providing unsurpassed precision and accuracy, lowering waste, and enhancing production efficiency, machines such as high-precision CNC turning centres help firms save time and money.

How to Improve Machining Precision and Accuracy?

Minimizing waste and manufacturing high-quality products depend on improved machining precision and accuracy. These are several strategies to get better:

· Regular Calibration: Machines are periodically calibrated to guarantee their operation within the intended tolerances.

· Use High-Quality Tools: Purchasing sharp, long-lasting cutting tools guarantees constant results and improved accuracy.

· Minimize Tool Wear: Changing tired tools immediately helps avoid machining process mistakes.

· Maintain Optimal Speeds: Correct feed rates and spindle speeds running machines guarantee accurate and precise components.

· Perform Routine Maintenance: Frequent maintenance and cleaning of machines helps to prevent mechanical problems generating mistakes.

· Stable Environment: Temperature swings and vibrations can affect accuracy; a controlled atmosphere reduces these influences.

Machining accuracy and precision will be much improved by applying these techniques.

Conclusion:

Producing high-quality products that meet industrial machining standards depends on accuracy and precision. Accuracy ensures that each component is produced to the appropriate standard, while precision ensures repeatability. For industries that require exacting standards, advanced CNC machines offer an ideal combination of both, making them absolutely indispensable.

Manufacturers can increase general product quality, lower waste, and achieve higher efficiency by choosing the correct equipment. If you want to improve your machining techniques, consider selecting CNC machines that are accessible at CNC Yangsen.