Is hot melt adhesive on diapers harmful?

Why do diapers use hot melt adhesive?

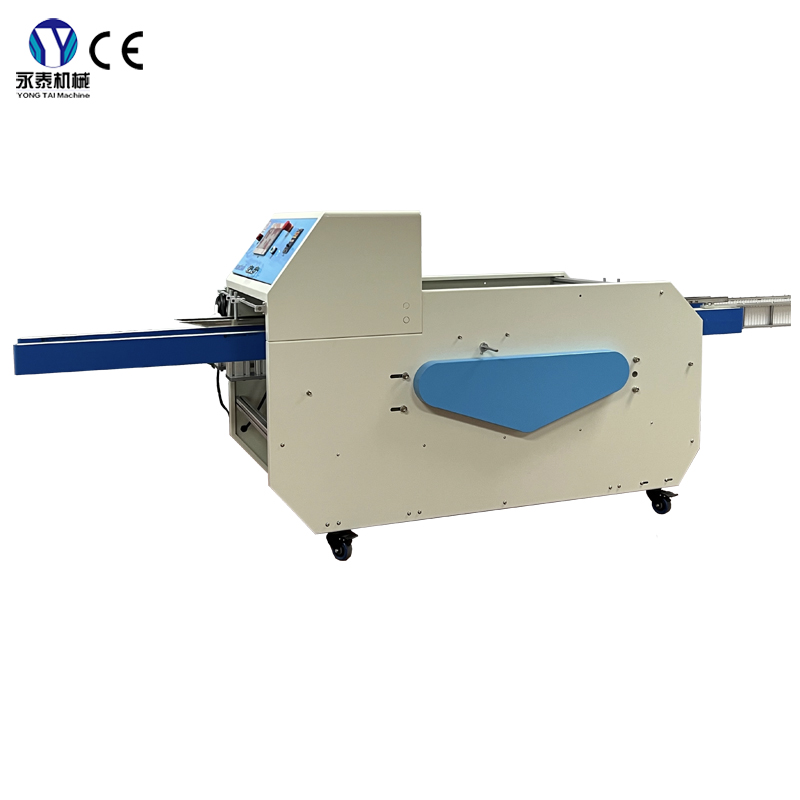

The production process of diapers is a relatively complex combination process, which is composed of surface non-woven fabrics, water-absorbent cores, PE composite bottom films, magic buckles and front waist stickers, anti-side leakage non-woven fabrics, elastic bands and many other materials. The combination of the above materials is bonded through hot melt adhesive, which is the current production process of all diapers. It can be seen that "hot melt adhesive" will be present in the normal production process of diapers.

What are the methods of gluing diapers?

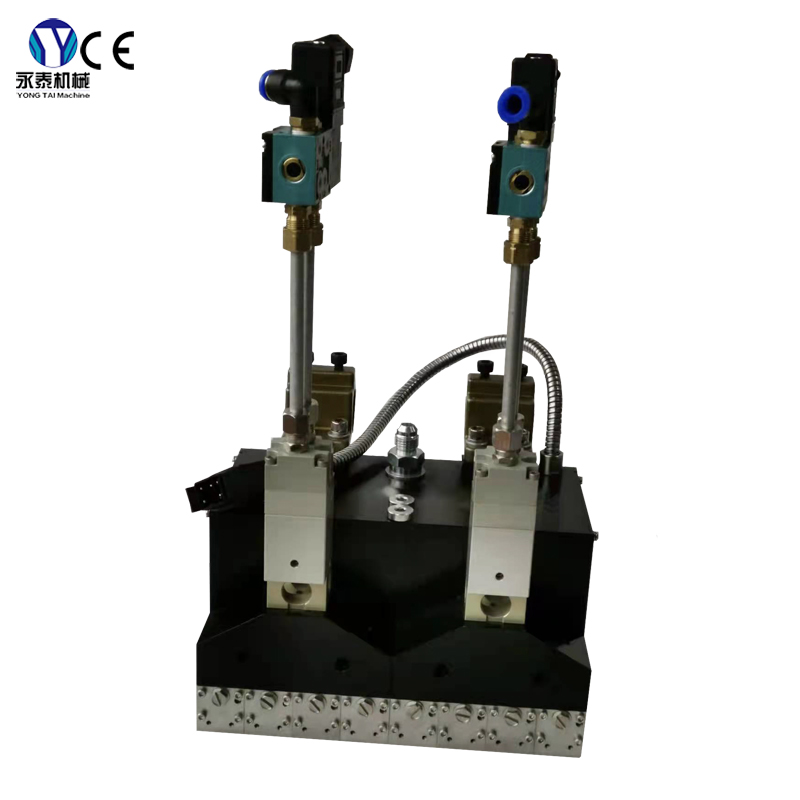

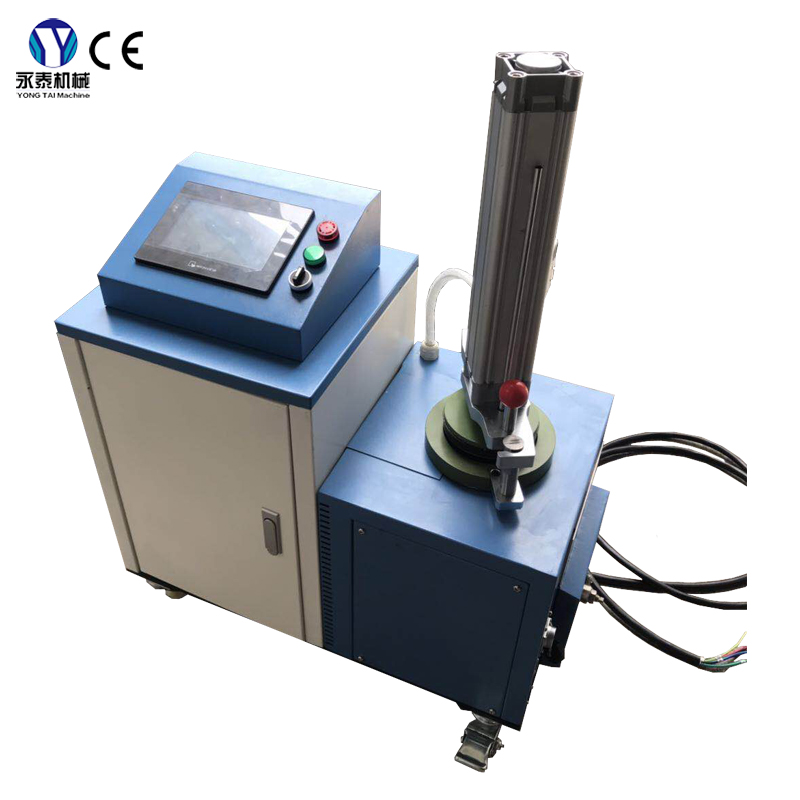

There are two ways to apply glue. One is spraying glue, and the other is scraping glue. These two methods use a spray gun and a scraper gun. The spray gun uses several small holes in the spiral to blow out the gas at a set pressure. , the glue squeezed out from the glue holes surrounding the pores is sprayed in a spiral shape on the surface of the material to be composited, and then passes through a series of pressure rollers to firmly composite the materials together.

Is the smell of hot melt glue toxic?

Hot melt collagen material consists of main resin, tackifier resin, diluent or softening oil, additives and other ingredients. The inherent smell of raw materials is an important source of the smell of hot melt adhesive.

During the production process, hot melt adhesive may also have new odor sources, and the odor can be reduced through production process control. During the logistics and transportation of hot melt adhesive, it may also be contaminated with new odors. But generally speaking, the slight smell contained in the hot melt adhesive itself is non-toxic.

Is hot melt glue harmful to babies?

Hot melt adhesive is non-toxic and odorless, and is an environmentally friendly chemical product. Its physical state changes with changes in temperature. Therefore, when hot melt adhesive is used in the production of diapers, the resulting glue is a production defect and belongs to the after-sales scope of the product, but it will not cause any harm to the human body.