Structural Steel Truss Fabrication Services for Conveyors: Precision Engineering for Bulk Material Handling

In industries where raw materials like coal, ore, and cement are moved across vast distances, structural steel truss fabrication services form the backbone of reliable conveyor systems. At CAFU Machinery, we combine over a decade of expertise in heavy steel fabrication with cutting - edge manufacturing technologies to deliver custom - engineered truss solutions that withstand the toughest operational demands.

Why Structural Steel Trusses Matter in Conveyor Systems

Structural steel trusses provide the critical support framework for belt and pipe conveyor systems, ensuring stability under heavy loads and harsh environmental conditions. Key advantages include:

• High Load Capacity: Designed to handle dynamic material loads under complex conditions

• Adaptability: Custom shapes (curved, inclined, or tapered) to navigate terrain challenges

• Durability: Long - lasting performance under complex geographical conditions and extreme climate situations

CAFU’s Expertise in Structural Steel Truss Fabrication

As trusted custom metal fabricators, we specialize in producing conveyor trusses that meet the customized standards specified in the client's drawings. Our end-to-end capabilities include:

1. Custom Design & Engineering

Client-Driven Solutions:

• Build from your CAD drawings or collaborate on new designs

• Optimize truss geometry for spans up to 24m (assembled from 12m modular sections)

Complex Geometry:

• Curved trusses with 15°–45° bend radii for route flexibility

• Inclined trusses (up to 30° angles) for elevation changes

2. Precision Manufacturing Process

Step 1: Material Preparation

• Laser/plasma cutting of steel plates

• CNC drilling of bolt holes

Step 2: Assembly & Welding

• High-quality gas shielded welding for main chords and diagonals

• Manual GTAW (TIG) welding for intricate joints

Step 3: Quality Assurance

• 100% visual inspection + 20% ultrasonic testing (UT) of critical welds

• Conduct full-scale pre-assembly checks

Step 4: Surface Treatment

• Shot blasting to Sa 2.5 cleanliness

• Epoxy-zinc primer + polyurethane topcoat

Industry Applications

Our heavy steel fabrication are engineered for reliability in:

|

Industry

|

Use Cases

|

|

Mining

|

Overland conveyors, transfer stations

|

|

Cement Plants

|

Clinker/cooler conveyors, raw mill feed systems

|

|

Power Generation

|

Fuel handling systems, ash conveyor supports

|

|

Steel Mills

|

Slag conveyors, raw material transport

|

Technical Advantages of CAFU Truss Systems

1. Modular Efficiency

• 12m container - friendly sections reduce shipping costs by 30%

• High – strength bolted connections (Grade 8.8/10.9) enable rapid on – site assembly

2. Customization Flexibility

• Variable depths (1.5–2.5m) to match conveyor belt widths (500–2,400mm)

• Optional walkways, maintenance platforms, and cable trays

3. Long – Term Reliability

• High - quality steel ensures an extremely long fatigue life

• Strict anti - corrosion construction processes and high - quality coatings ensure corrosion resistance in coastal/chemical environments and extend the service life of the coatings

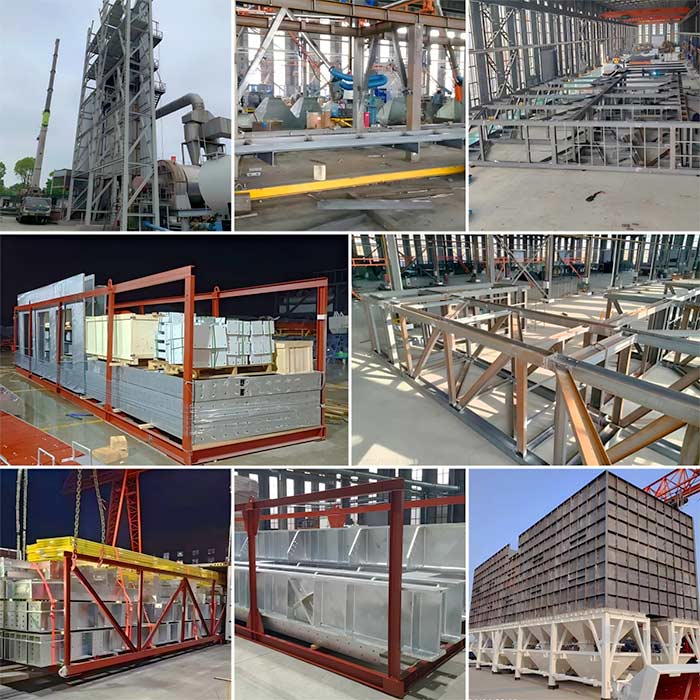

Case Study: Pipe Belt Conveyor Project for Steel Mills

This pipe belt conveyor project has a total length of 1050m. It is used to transport coal for the steel mills, with a transportation capacity of 1000t/h and a belt speed of 3.5m/s. Our company manufactures the structural truss systems.

Why Partner with CAFU?

• Proven Expertise: Multiple conveyor truss projects completed since 2015

• Advanced Facilities: 15,000㎡ workshop with 50-ton overhead cranes

• OEM Custom Metal Fabrication Services: Serving conveyor design units and project consortiums worldwide, providing high-quality conveyor components and price-competitive solutions

Elevate Your Conveyor Infrastructure Today

Whether you’re upgrading existing systems or designing new bulk handling networks, CAFU’s heavy steel fabrication services deliver:

• 15% faster installation through modular designs

• Ensure to extend the coating service life of the Structural Steel Truss by 20% through high-quality anti-corrosion processes

• 100% compliance with your operational specs