Application Industries Of Explosion-proof Mold Temperature Controller

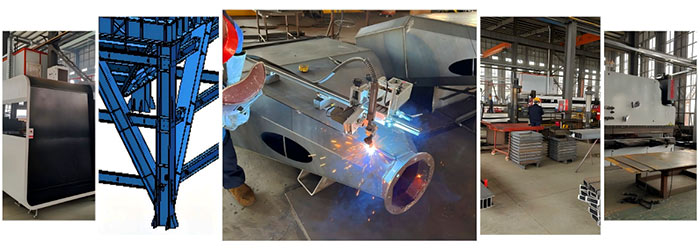

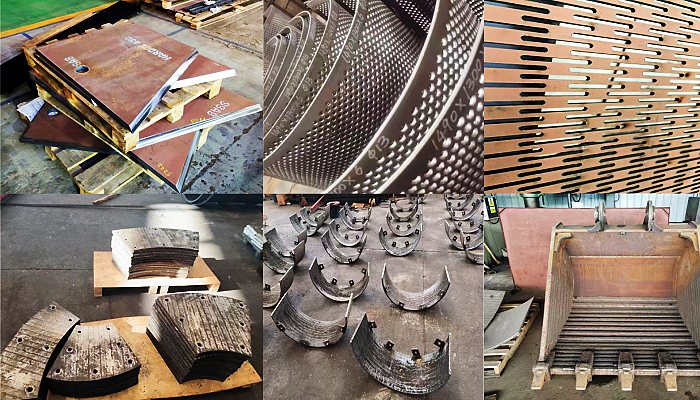

Hengde Company, a renowned enterprise with years of in - depth experience in the temperature control equipment field, has developed and produced explosion - proof mold temperature controllers that play a crucial role in multiple industries. These products are backed by advanced technology and reliable quality. Here are some common scenarios where explosion-proof mold temperature controllers are utilized:

Chemical Industry

- Reaction Kettle Temperature Control: In chemical production, various chemical reactions occur in reaction kettles, involving flammable and explosive chemicals, such as hydrocarbon reactions in petrochemicals and nitration reactions in fine chemicals. Hengde's explosion - proof mold temperature controllers adopt multiple explosion-proof technologies and feature a highly precise temperature control system. They can accurately control the temperature of the reaction kettle, ensuring that the reaction proceeds within a safe temperature range and preventing explosions caused by temperature runaway. In addition, mold temperature controllers are also used in material drying, distillation, and rectification processes in the chemical industry.

Many large - scale chemical enterprises have significantly enhanced production safety and reaction efficiency after adopting Hengde's explosion - proof mold temperature controllers.A large - scale petrochemical enterprise commented: "Since the introduction of Hengde's explosion - proof mold temperature controller, the temperature control accuracy of our reaction kettles has reached an unprecedented level. The potential safety hazards in the production process have been greatly reduced, and both production output and product quality have improved significantly. We truly feel at ease with Hengde's products."

Pharmaceutical Industry

- Drug Synthesis: Drug synthesis reactions have strict temperature requirements, and some of the chemical raw materials or intermediates used in the synthesis process are flammable and explosive, such as some compounds containing nitro and amino groups. With its in - depth understanding of pharmaceutical processes, Hengde Company's explosion - proof mold temperature controllers can accurately control the temperature, ensuring the smooth progress of the synthesis reaction and production safety. Many well - known pharmaceutical companies have chosen Hengde's products to provide stable and reliable temperature control support for drug research and production.

Rubber Industry

- Rubber Vulcanization: The rubber vulcanization process requires precise control of temperature and time to ensure the performance of rubber products. The vulcanization workshop contains a large amount of rubber raw materials and additives, some of which are flammable and explosive. Hengde's explosion - proof mold temperature controllers can safely provide the required heat during the vulcanization process, ensuring the vulcanization effect. Many rubber production enterprises have reported that the product defect rate has decreased significantly after using Hengde's explosion - proof mold temperature controllers.

- A rubber tire manufacturing enterprise feedback: "After using Hengde's explosion - proof mold temperature controller for rubber vulcanization, the product defect rate has dropped from the original 8% to 3%, greatly improving our production efficiency, and the product quality has become more stable."

- Rubber Mixing: In the rubber mixing process, to evenly disperse various compounding agents in the rubber, the temperature of the mixing equipment needs to be controlled. During the mixing process, potential hazards such as static electricity may occur. Hengde's explosion - proof mold temperature controllers are equipped with professional static elimination devices, which can effectively avoid fire or explosion accidents caused by static electricity and ensure the continuity of production.

New Energy Industry

- Lithium - ion Battery Production: In the processes of lithium - ion battery anode and cathode material preparation and battery assembly, flammable and explosive organic solvents and chemicals are used. For example, in the production of lithium - ion battery anode materials, Hengde's explosion - proof oil - circulation mold temperature controllers can provide precise temperature control, ensuring that the chemical reactions in the reaction kettles occur at a safe temperature and improving the performance of the anode materials, helping new energy enterprises enhance their product competitiveness.

A new energy battery production enterprise commented: "Hengde's explosion - proof oil - circulation mold temperature controller has been of great help to our lithium - ion battery anode material production. The product performance has been significantly improved, making our products more competitive in the market."

Other Industries

- Printing and Dyeing Industry: In the processes of dye processing and fabric heating, some dyes and organic solvents are flammable and explosive. Hengde's explosion - proof mold temperature controllers are used to control the temperature, which can improve the dyeing quality and production efficiency while avoiding safety accidents, bringing a more stable production environment to printing and dyeing enterprises.

- Electronics Industry: In the production of some electronic products, such as chip manufacturing and circuit board soldering, the processes need to be carried out at specific temperatures, and the production environment may contain flammable and explosive gases or dust. Hengde's explosion - proof mold temperature controllers can provide stable temperature control, ensuring the safety of the production process and product quality, and are favored by many electronic manufacturing enterprises.

- Laboratories with Special Requirements: Laboratories such as petrochemical laboratories and explosive research laboratories may handle flammable and explosive samples or conduct related experiments. Hengde's explosion - proof mold temperature controllers can be used to control the temperature of experimental equipment, ensuring the safe progress of experiments and providing safe and reliable temperature control solutions for scientific researchers.

When you are looking for a reliable explosion-proof mold temperature controller, Hengde Company is undoubtedly your best choice. With years of industry experience, advanced technology, reliable quality, and a good reputation among numerous customers, Hengde stands out in the field of explosion-proof mold temperature controllers. Choosing Hengde means choosing safety, efficiency, and quality. Hengde will escort your production and scientific research work.

Choose Hengde,Choose Perfect Mold Temperature Controller!