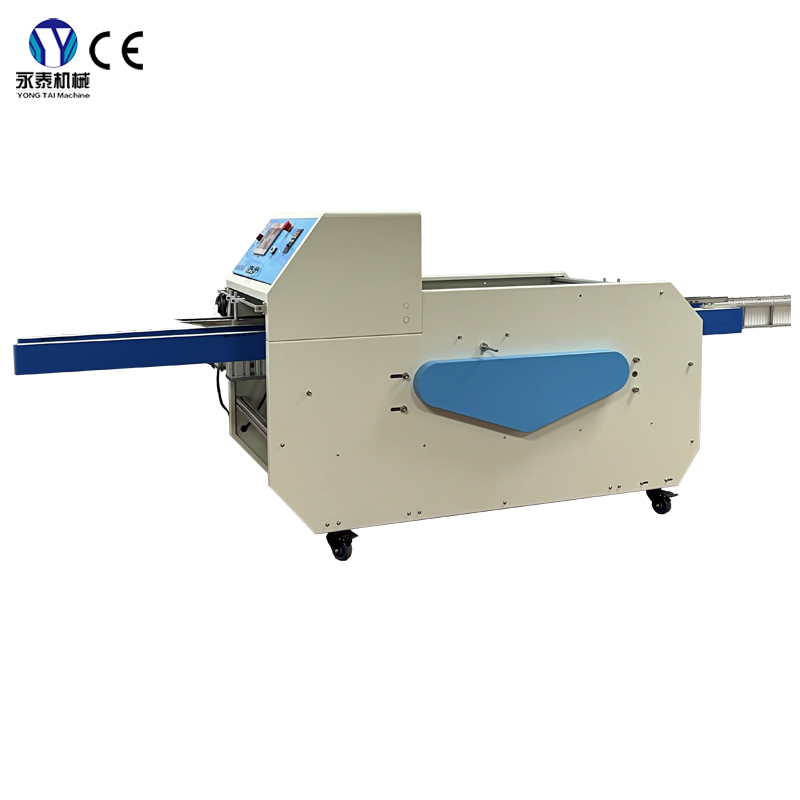

Unleashing Precision and Power The Unique Features and Advantages of the Tiger Shear

Tiger shear have the advantages of small size, light weight, low inertia, low noise, smooth movement, convenient operation, flexibility, large shearing section, easy adjustment of the cutting body, etc., and are safe to operate and use. They are often used in scrap recycling enterprises, scrap steel plants, smelting and casting enterprises to cold shear various shapes of steel and various structures of metal. The purpose of the shearing machine is to cut to size, cut heads, cut tails, cut edges, cut samples, and remove local defects of rolled products.

Working process of tiger shears

Adjust parameters: Adjust the position and shearing pressure of the shear blade according to the thickness and hardness of the metal material.

Placing metal materials: The metal materials to be sheared are placed on the workbench of the scrap metal shears.

Starting equipment: Start the power system of the tiger head shears through the control system.

Shearing metal materials: The shear blade shears the metal materials at high speed and high pressure to achieve fast and accurate shearing effects.

Features of tiger shear:

(1) Hydraulic drive, stable operation, no vibration.

(2) Simple infrastructure, no need for base screws for installation.

(3) PLC control is adopted, and users can choose manual or automatic operation.

(4) Automatic feeding mechanism can be added according to user requirements.

Advantages of tiger shears

1. The tiger shear uses a plate chain silo to achieve smooth feeding. This can avoid the problem of material extrusion and rumbling when feeding with traditional feeding mechanisms.

2. The shearing cylinder of the scrap metal tiger shearing machine adopts ball joint connection, which improves the stability and life of the cylinder. This also adds a front plate guide device, which has low noise, good stability and strong reliability.

3. It adopts hydraulic drive, which is easy to operate and simple to maintain. It is easy to install, and no foot screws are required to install the tiger shear.